Qualities

Qualities of Kerwood® foamed ceramic microspheres

and materials made of them

Lightweight filler Kerwood® is designed to improve technical qualities of materials, make them lighter, as well as increase the output of finished products. Low weight of the granules, impressive array of advantages and possible applications, as well as economic benefits are the reasons why Kerwood® foamed ceramics is highly demanded at the market.

Kerwood® ceramics

The filler is a light spherical granule with a dense shell and internal structure resembling a solid soap foam. This form allows granules to work as efficiently as possible in the final materials (for example, when plastering,

the effect of «rolling» occurs).

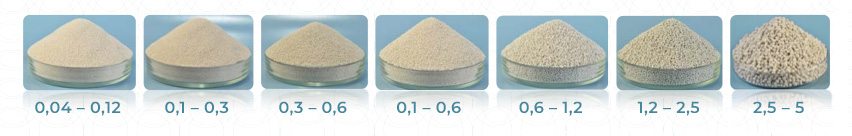

Kerwood foamed ceramics ranges from 0.04 mm to 5 mm and is divided into seven standard fractions.

Sizes of the standard produced fractions (granule diameter in mm)

- Kerwood® filler’s inner cells have a complex shape, which provides granules with high mechanical strength.

- Kerwood® foamed ceramic microspheres have a light tint, which is important from the design point of view, for example, when used in the artificial stone or paints.

- There are no organic impurities: 75-80% of the filler consists of silicon oxide, the rest is metal oxides.

Chemical composition

| Component |

SiО₂ |

Al₂O₃ |

Na₂O+K₂O |

Fe₂O₃ |

MgO |

Other |

|---|---|---|---|---|---|---|

|

% |

69.78 |

8.03 |

14.58 |

3.89 |

1.06 |

2.66 |

Foamed ceramic has an extremely low potential reactivity, allowing to refuse special additives with cement-containing materials.

Kerwood® filler is produced serially, the stability of its characteristics is confirmed by certificates issued officially by accredited laboratories.

Production of granules

Kerwood® foamed ceramics is made of diatomaceous or trefoil, formed from the fossil remains of diatoms over 30 million years ago. Diatomite contains 65-90% of silicon oxide (SiO₂) and stable oxides (Al₂O₃, Fe₂O₃ and others).

The production cycle is divided into several main stages

- Crushing of raw materials

- Drying of raw materials

- Mixture of charge

- Granulation

- Foaming

- Dividing of fractions

After each stage the material undergoes laboratory testing.

The main advantages of Kerwood® lightweight filler

- Light weight

At a density of 160 kg / m³ (for a fraction of 2.5-5 mm), the filler significantly benefits in mass in comparison to its counterparts. As a result, it is possible to significantly increase the yield of products, reducing the weight of the finished material and the costs of the binder. - Durability

Service life of the filler is not less than 100 years, which is confirmed in laboratory tests. Durability is achieved due to the strength and hermetic closure of the internal structure. - Mechanical strength

Strength of the granules for compression is sufficient even for their use under high pressure in the composition of grouting mortars. When compressed in a cylinder, the strength of the microspheres is from 0.6 to 12 MPa. These characteristics do not decrease with the surface water saturation, even as the time goes by. - Heat and sound insulation qualities

Thermal conductivity of Kerwood® granules, depending on their size, is only 0.05 to 0.09 W / mK. Like the lightweight of granules, this quality exists due to the porous internal structure, because the air is an excellent heat insulator. Similarly Kerwood® foamed ceramics is effective for delaying sound (panels made with our filler are not only suitable for soundproofing, but for controlling the acoustics of rooms as well). - Fire resistance

The granules are absolutely incombustible: they consist of the melt of higher oxides, and such substances basically are not capable of oxidation (and hence of ignition). Materials with Kerwood® filler can effectively counteract the spread of fire. - Neutrality and resistance to impacts

Foamed ceramic microspheres do not react with any substances, they are resistant to the effects of chemically aggressive environment. - Moisture resistance

Due to the structure of the closed cells and the whole outer shell, moisture absorption of Kerwood® granules is from 4 to 7% by weight. This is approximately 15 times less than the one of expanded clay. And in comparison with the expanded vermiculite moisture absorption of the foamed ceramics is approximately 100 times lower. - Safety and hygiene

Since the material is completely mineral, it does not represent a nutrient medium for the development of bacteria and fungi, and is not prone to decay. Granules do not emit any harmful substances into the atmosphere, even when being heated.

Thanks to all these qualities, Kerwood® lightweight filler is suitable for a wide range of applications. It is successfully used in the production of modern building materials: lightweight concrete, polymers, dry building mixtures, paints, as well as oil and gas and automotive industries.

ru

ru  en

en